Numanova, an Italeaf Group company specialised in the production of metal powders used as raw materials in additive manufacturing (or 3D printing), announces the start of its industrial activity at its production plant in Nera Montoro (Narni, Italy). In fact, the first order for the production of grade 23 titanium powders for special applications in the aeronautical and space sectors and for 3D printing is currently being completed and will be delivered to a specialised trader for final marketing. This is an innovative production that uses Argon in fusion for gas-atomisation, as an inert process gas for the production and processing of the highest quality metal powders.

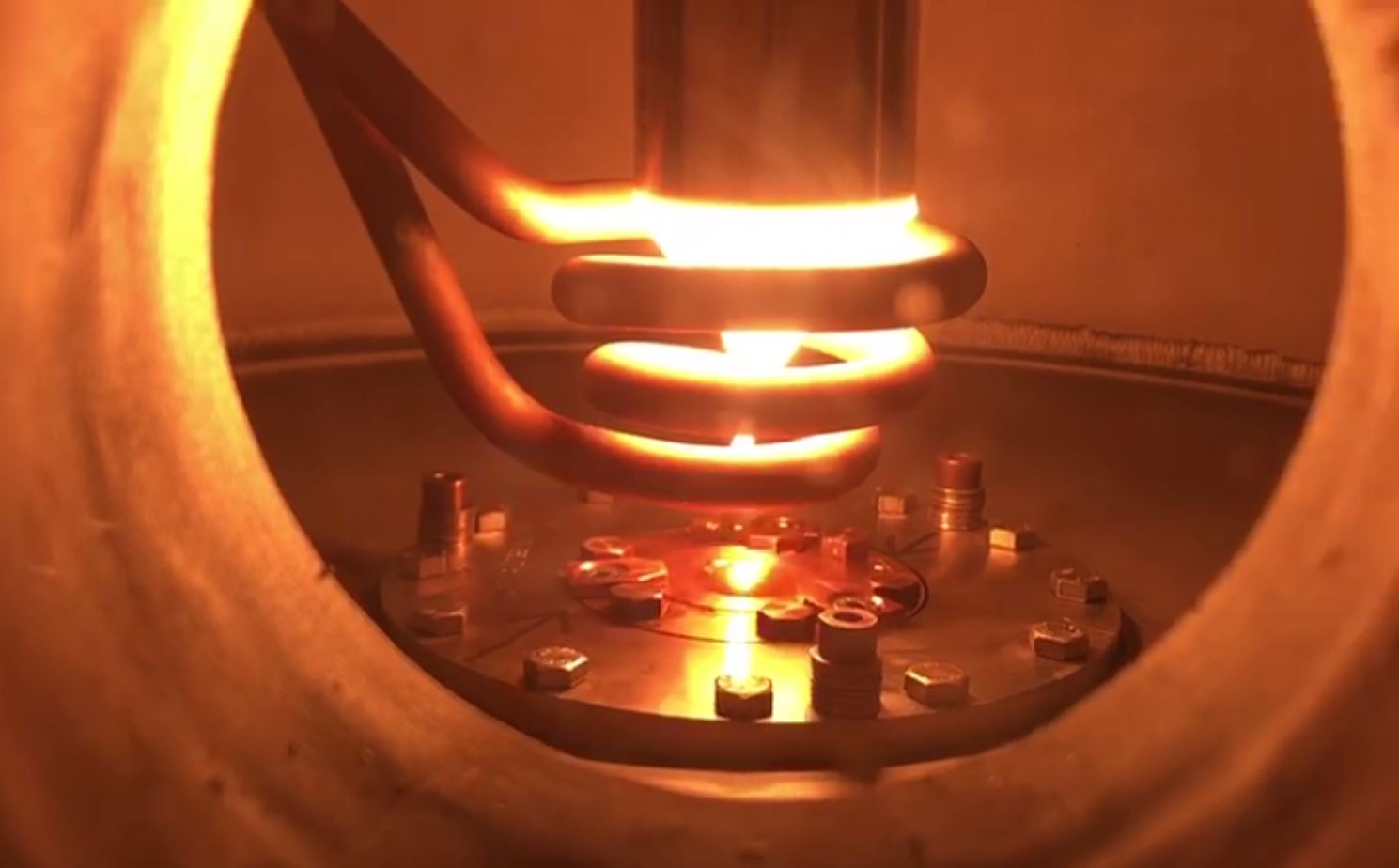

With the first fully operational castings made in the Nera Montoro plant, the EIGA (Electrode Induction-melting Inert Gas Atomization) plant comes into operation. This plant allows an advanced process for the production of metal powders from titanium alloys, aluminium, refractory materials, ceramics and precious alloys for special applications and Additive Manufacturing.

Numanova has the most advanced and robust gas-atomisation technology for the production of metallic powders available today on the international market, based (when fully operational) on 2 plants with installed productivity up to 800t/year.

The process consists of atomising a controlled flow of molten metal into very fine droplets by means of a high-pressure Argon jet. As they solidify, the droplets form a highly spherical micrometric powder. Starting from these powder alloys, after a careful and rigorous process of screening, certification and qualification of its product, Numanova is able to provide the market with a wide range of metal powders for the additive manufacture of parts with complex geometries equipped with new functions (for example, for the manufacture of prostheses in the biomedical sector, turbine components in the aeronautical and energy sectors, in the luxury industry).